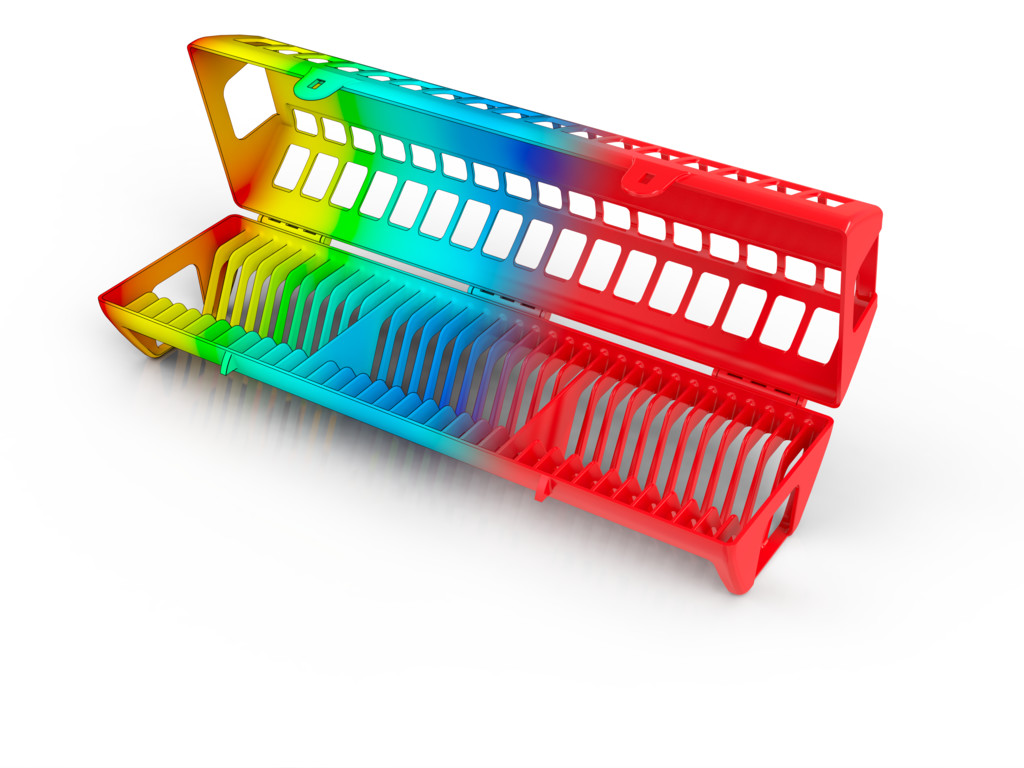

SOLIDWORKS Plastics

SOLIDWORKS Plastics delivers easy-to-use simulation for analyzing plastic parts and injection molds. It simulates how melted plastic flows during the injection molding process to predict manufacturing-related defects so you can quickly evaluate part manufacturability while you design.

SOLIDWORKS Plastics Predict and avoid manufacturing defects in plastic part and injection mold designs, eliminating costly rework, improving part quality, and decreasing time to market.

SolidWorks Plastics comes in three features :

Fundamental – SolidWorks Plastics

SOLIDWORKS Plastics Standard

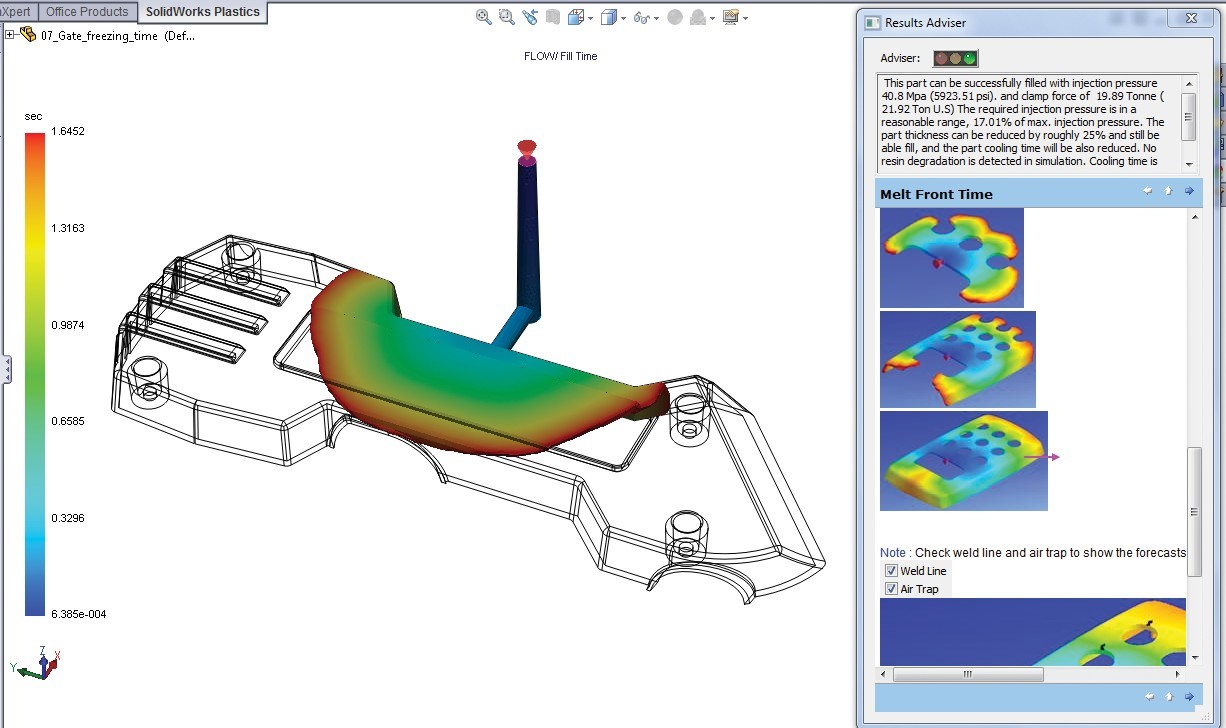

For plastics part designers, SOLIDWORKS Plastics Standard enables you to optimize parts for manufacturability in the early stages of design.

Easy to learn and use, SOLIDWORKS Plastics Standard is fully embedded within the SOLIDWORKS CAD environment so you can analyze and modify designs at the same time you optimize for form, fit, and function.

SOLIDWORKS Plastics Professional

For plastics part designers, SOLIDWORKS Plastics Professional enables you to optimize parts for manufacturability in the early stages of design.

Easy to learn and use, SOLIDWORKS Plastics Professional is fully embedded within the SOLIDWORKS CAD environment so you can analyze and modify designs at the same the time you optimize for form, fit, and function.

SOLIDWORKS Plastics Premium

SOLIDWORKS Plastics Premium includes all the power of Plastics Professional with the addition of advanced simulation functionality to analyze mold cooling line layouts and part warpage.

Optimizing the cooling line minimizes cycle times and decreases manufacturing costs.